IoT Adoption Is Accelerating, but the Real Challenge Is Going Further

The IoT is no longer an emerging technology sitting on the sidelines. According to a GSMA global survey, IoT has become a fundamental driver of digital transformation. Among organizations actively pursuing digital transformation, 88% have already adopted IoT in some form.

On the surface, this looks like a success story. IoT adoption is widespread, and connected devices are now part of everyday business operations across industries.

But the same report reveals a striking contradiction. While adoption rates are high, only 36 percent of these organizations are using IoT devices in advanced or transformative ways. Most deployments remain limited to basic monitoring or isolated use cases, failing to deliver their full potential value.

This gap between “having IoT” and “using IoT well” defines the current stage of IoT adoption. Understanding why this gap exists, and how organizations can move beyond it, is now critical.

What is IoT Adoption and Why Does It Matter?

IoT adoption is not simply about deploying sensors or connecting devices to the internet. At its core, it refers to how deeply connected technologies are integrated into business processes, decision-making, and value creation.

When organizations adopt IoT effectively, they gain continuous visibility into how products, assets, and environments behave in the real world. This data helps businesses understand customer preferences, usage patterns, and operational inefficiencies that were previously hidden.

The importance of IoT adoption lies in what this insight enables. With accurate, real-time data, companies can improve products and services, optimize workflows, and respond faster to changing conditions. Over time, this leads to higher efficiency, stronger customer satisfaction, and sustainable revenue growth.

In short, IoT adoption matters because it turns physical activity into actionable intelligence.

The Undeniable Value Proposition: Core Benefits of IoT Adoption

Operational Efficiency

One of the most immediate benefits of IoT adoption is improved operational efficiency. Connected systems enable automation, streamline workflows, and reduce manual intervention. Machines can report their own status, assets can be tracked automatically, and processes can be optimized based on real usage data rather than assumptions.

This reduces downtime, cuts waste, and helps organizations do more with fewer resources.

Data-Driven Decision Making

IoT adoption replaces delayed reporting with real-time visibility. Leaders can see what is happening now, not weeks later. More importantly, historical IoT data enables predictive insights.

Patterns in performance, wear, or behavior allow organizations to anticipate problems and opportunities before they occur. Decision-making becomes proactive rather than reactive.

Creating New Business Models

As IoT adoption matures, companies are moving from selling products to offering services or usage‑based models. Connected devices enable billing based on actual use or outcomes rather than upfront purchases. This “product‑as‑a‑service” model combines sensors, remote monitoring, and analytics to support performance‑based contracts.

For example, industrial equipment vendors can charge based on machine operating hours or output, bundling predictive maintenance and remote monitoring to generate steady revenue and align success with customer outcomes.

Enhanced Customer Experience and Security

IoT adoption improves customer experience by enabling personalized services, faster issue resolution, and more reliable products. For example, connected devices can track usage patterns and automatically adjust settings to better meet individual customer needs. In service industries, IoT-enabled systems allow support teams to detect and resolve issues remotely, reducing downtime and minimizing disruption.

When designed with security in mind, connected systems also strengthen protection by continuously monitoring devices, identifying anomalies in real time, and alerting operators to potential threats before they escalate. This proactive approach helps safeguard sensitive data, prevents operational interruptions, and builds customer trust, making IoT adoption not only a tool for efficiency but also a driver of safer, more satisfying user experiences.

The State of IoT Adoption: Key Insights & Drivers

The Internet of Things has become a transformative force, with the global IoT end-user solutions market projected to reach $1.6 trillion by 2025. Billions of devices worldwide are connected, reshaping industries, cities, and everyday life.

Global Adoption Patterns

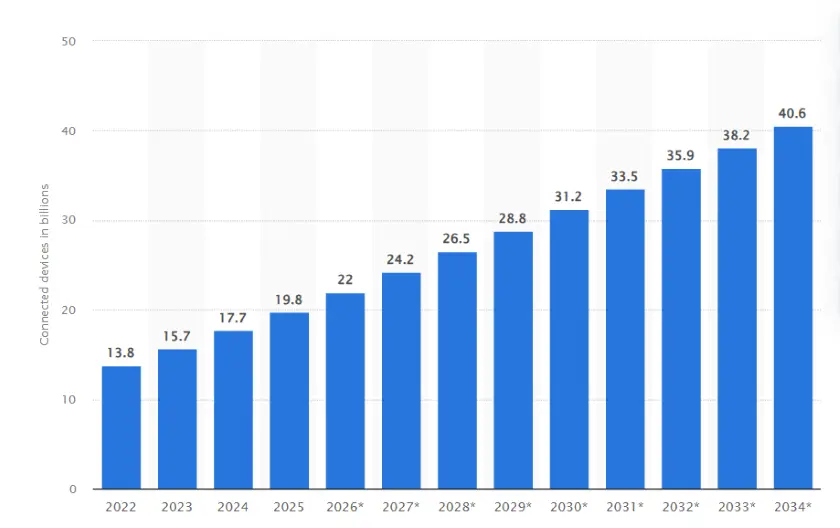

By 2024, there will be over 17 billion IoT devices globally, including 5.4 billion in North America. Europe generated $225 billion in IoT revenue in 2023, expected to nearly double by 2028. In Asia-Pacific, China will host around 8 billion connected devices by 2033, supported by technological advancements and government initiatives. Other regions, like Africa, are growing steadily but face infrastructure and regulatory challenges.

*source: ©Statista 2025

Key Drivers

Operational efficiency: Real-time monitoring and automation reduce downtime and costs.

Data-driven insights: IoT enables predictive analytics across equipment, supply chains, and environments.

New business models: Pay-per-use and outcome-based services transform product sales into recurring revenue.

Urbanization and sustainability: Smart cities and energy-efficient systems accelerate adoption.

IoT Adoption Industry Leaders and Use Cases

Manufacturing

Manufacturing remains one of the most advanced and impactful adopters of IoT, driven by the need for higher efficiency, precision, and operational visibility. Recent industry research shows that around 62% of manufacturers already use IoT technologies in production or assembly environments, reflecting a broad recognition of IoT’s value in modern factories.

A key focus area is real-time operational visibility. However, fewer than 60% of manufacturers currently have real-time insight into machinery status, materials, or work-in-progress. This visibility gap contributes to persistent challenges such as misplaced tools and materials, difficulty measuring efficiency, and production sequencing disruptions—issues reported by roughly one-third of manufacturers.

IoT solutions such as real-time location systems (RTLS), sensor-based monitoring, and predictive analytics are increasingly deployed to close this gap. By tracking assets, tools, and workflows in real time, manufacturers can identify hidden inefficiencies, reduce downtime, and align actual operations more closely with production plans.

Despite economic pressures from inflation, energy costs, and supply chain, manufacturers continue to invest. Around three-quarters of organizations report an increased willingness to invest in IoT, viewing data-driven automation and visibility as essential to resilience, cost control, and long-term competitiveness.

Automotive, Energy, and Utilities

Automotive, energy, and utilities are among the strongest industry leaders in IoT adoption, playing a central role in broader digital transformation efforts. According to GSMA Intelligence, 88% of enterprises pursuing digital transformation already use IoT, with particularly strong uptake across mobility, utilities, and energy sectors.

In these industries, IoT enables large-scale monitoring of vehicles, infrastructure, and energy assets, supporting use cases such as predictive maintenance, remote diagnostics, smart grids, and fleet optimization. These capabilities help organizations reduce outages, improve safety, and balance supply and demand more effectively.

However, adoption is uneven in maturity. While IoT usage is widespread, only about 36% of organizations have moved into advanced IoT deployments. High implementation costs, security concerns, and integration complexity remain key barriers—especially for large, geographically distributed systems common in utilities and energy networks.

Connectivity innovation is helping address these challenges. eSIM and iSIM technologies are expected to power over 75% of cellular IoT by the end of the decade, enabling more flexible, scalable, and globally interoperable deployments. Industry-wide standardization is increasingly seen as critical for reducing costs, improving security, and enabling cross-border IoT operations at scale.

Smart Cities, Logistics, and Agriculture

Beyond heavy industry, IoT adoption is reshaping cities, supply chains, and food systems worldwide.

In smart cities, IoT sensors support traffic management, energy-efficient buildings, environmental monitoring, and public safety systems. Smart grids and building management platforms use real-time data to reduce energy waste, improve reliability, and support the integration of renewable energy sources—helping cities address sustainability and resilience challenges.

In logistics and supply chains, IoT enables real-time asset tracking, fleet monitoring, and condition sensing across goods in transit. GPS-enabled IoT devices provide visibility into location, movement, and handling conditions, helping organizations reduce losses, optimize routes, and respond quickly to disruptions across increasingly complex global networks.

Agriculture is also experiencing rapid IoT-driven change. Sensors monitoring soil conditions, weather, livestock health, and equipment performance allow farmers to optimize irrigation, fertilizer use, and crop yields while conserving resources. As demand for food rises and climate pressures intensify, IoT-supported precision agriculture is becoming a key tool for sustainable farming and food security.

Across these sectors, the common value of IoT lies in real-time data, automation, and visibility, enabling better decisions, lower costs, and more sustainable operations at scale.

Navigating the Challenges: The Roadblocks to Scale

Cost and Complexity

While IoT adoption is now widespread, scaling deployments beyond basic use cases remains a major hurdle. Industry research shows that nearly nine out of ten organizations engaged in digital transformation already use IoT, yet only a minority have progressed to advanced, large-scale implementations. The primary reason is cost.

IoT projects often involve more than just device purchases. Expenses quickly accumulate across connectivity, system integration, cloud infrastructure, long-term maintenance, and lifecycle management. In many regions, enterprises identify implementation and operational costs as the single largest barrier preventing broader rollout. These challenges are especially pronounced in industries operating across multiple countries, where connectivity requirements, compliance rules, and deployment models vary widely.

Technical complexity compounds the issue. Managing thousands or millions of connected endpoints requires specialized expertise, robust support models, and scalable connectivity architectures. As a result, many organizations remain stuck at pilot or limited deployments, unable to justify expansion without clearer cost control and operational simplicity.

Security Concerns

Security remains one of the most persistent obstacles to scaling IoT adoption. As the number of connected devices worldwide continues to grow into the tens of billions, each endpoint becomes a potential entry point for cyber threats. This expanding attack surface has elevated IoT security from a technical concern to a board-level risk.

Industry data shows that while most organizations have already integrated IoT, a significant share have experienced security incidents linked to connected devices in recent years. These incidents range from data breaches to service disruptions, often caused by weak authentication, unpatched firmware, or poorly secured device communications.

The challenge is magnified in industrial and critical infrastructure environments, where IoT systems support energy grids, manufacturing lines, transportation networks, and public services. In these settings, a single vulnerability can disrupt operations at scale, resulting in financial loss, safety risks, and regulatory exposure.

Integration Challenges

Integration remains a major technical barrier on the path to scalable IoT adoption. Most organizations operate within complex IT and operational technology environments, where legacy systems coexist with newer digital platforms. Introducing IoT into this landscape often requires bridging gaps between outdated infrastructure and modern, data-driven architectures.

The challenge intensifies in multi-vendor environments, where devices, connectivity platforms, and software tools come from different suppliers. Inconsistent data formats, incompatible protocols, and fragmented management tools can significantly increase deployment time and cost. Instead of delivering real-time insight, IoT systems risk becoming isolated data silos.

Technology Fragmentation and the Lack of Standards

Technology fragmentation continues to limit IoT’s ability to scale efficiently. In the absence of widely adopted standards, many IoT solutions remain highly customized and proprietary, locking organizations into specific vendors or regional implementations.

This lack of standardization drives up costs in several ways. Enterprises must redesign solutions for different markets, retrain teams on multiple platforms, and manage parallel systems that do not interoperate. Over time, these inefficiencies make IoT deployments harder to expand and maintain.

A Practical Roadmap for Successful IoT Adoption

Successfully scaling IoT adoption requires more than connecting devices. It demands deliberate choices around standards, security, and long-term partners. As IoT moves from experimentation to business-critical infrastructure, organizations need a roadmap that reduces risk while preserving flexibility.

Prioritize Open Standards and Future-Proof Connectivity

IoT is now central to digital transformation, yet many deployments fail to scale because of early technology decisions. Connectivity standards are a key factor in long-term success.

The shift toward eSIM and iSIM reflects an industry move away from rigid, market-specific designs toward more flexible and scalable connectivity. These technologies simplify provisioning, reduce operational overhead, and support global deployment. Open specifications such as SGP.32 further improve interoperability, helping organizations avoid vendor lock-in and repeated regional customization.

Choosing open, standards-based solutions is both a cost-control strategy and a form of future-proofing, enabling IoT systems to adapt as networks, regulations, and business requirements evolve.

Security by Design

As IoT deployments expand, security risks increase alongside them. When connected devices support core operations, security must be embedded from the start rather than added later.

Industry guidance consistently points to a security-by-design approach, covering device identity, encrypted communications, controlled access, and lifecycle monitoring across hardware, connectivity, and cloud layers. Organizations that adopt this mindset early are better equipped to scale securely, meet regulatory expectations, and avoid costly retrofits that slow IoT maturity.

Choose Partners That Enable Scale, Not Complexity

Even with the right standards and security strategy, successful IoT adoption depends on execution. Partner selection plays a decisive role.

Enterprises increasingly prioritize vendors that combine global coverage, local support, and proven technical capability, while also supporting long-term commercial collaboration. The right partner goes beyond supplying devices, helping streamline deployment, manage regional requirements, and support growth as use cases expand.

Providers such as Minew focus on scalable, standards-aligned IoT hardware and connectivity-ready designs. Its technology portfolio spans BLE, LoRaWAN, Wi-Fi, GPS, UWB, cellular, and satellite communication, enabling organizations to select the right connectivity model for different environments, from short-range indoor sensing to wide-area and remote deployments.

Equally important, extensive real-world deployment experience across industries allows IoT hardware solution providers like Minew to address practical challenges beyond hardware, including network planning, device management, and integration with existing systems. Working with vendors that understand both the technical and operational realities of IoT helps organizations move more efficiently from pilot projects to scalable, measurable business impact.

Conclusion

IoT adoption is already widespread, but scale and depth remain the real challenge. While most organizations have connected devices in place, many are still limited to basic use cases that deliver only a fraction of IoT’s potential value.

Closing this gap requires moving beyond connectivity alone. Open standards and flexible connectivity models help control costs and support long-term growth. Security must be built into IoT systems from the start, not added later. Just as importantly, working with the right partners—such as Minew—can simplify deployment, reduce complexity, and support expansion as use cases evolve.

When IoT adoption is approached strategically, it becomes more than a technical upgrade. It becomes a foundation for better decisions, stronger operations, and sustainable business impact.

Chat now

Chat now